About Our GRP Solutions

Oasis Metal are a trusted supplier of Glass Reinforced Plastic (GRP) also known as Fibreglass Reinforced Plastic (FRP). We provide high-performance solutions customised to meet the most demanding of environments. Oasis offers a full technical and customer service, that delivers custom-tailored products to meet your project needs, and timelines.

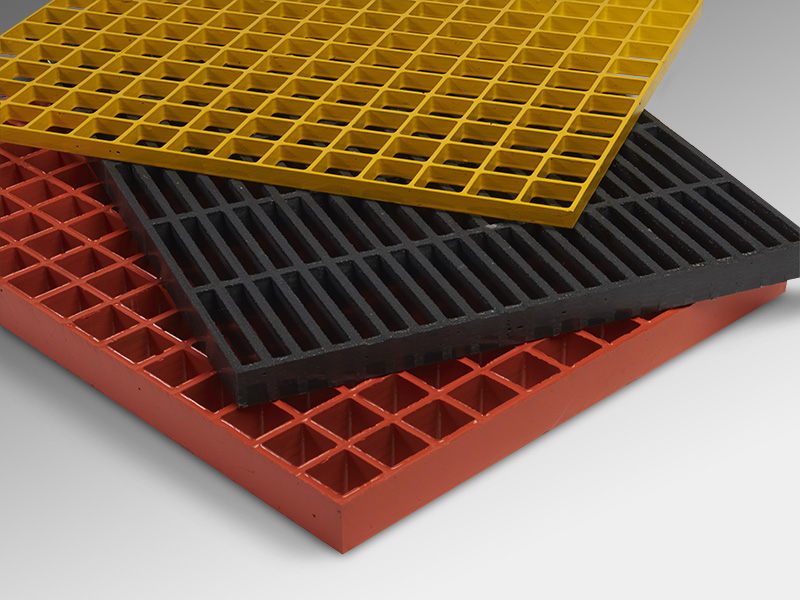

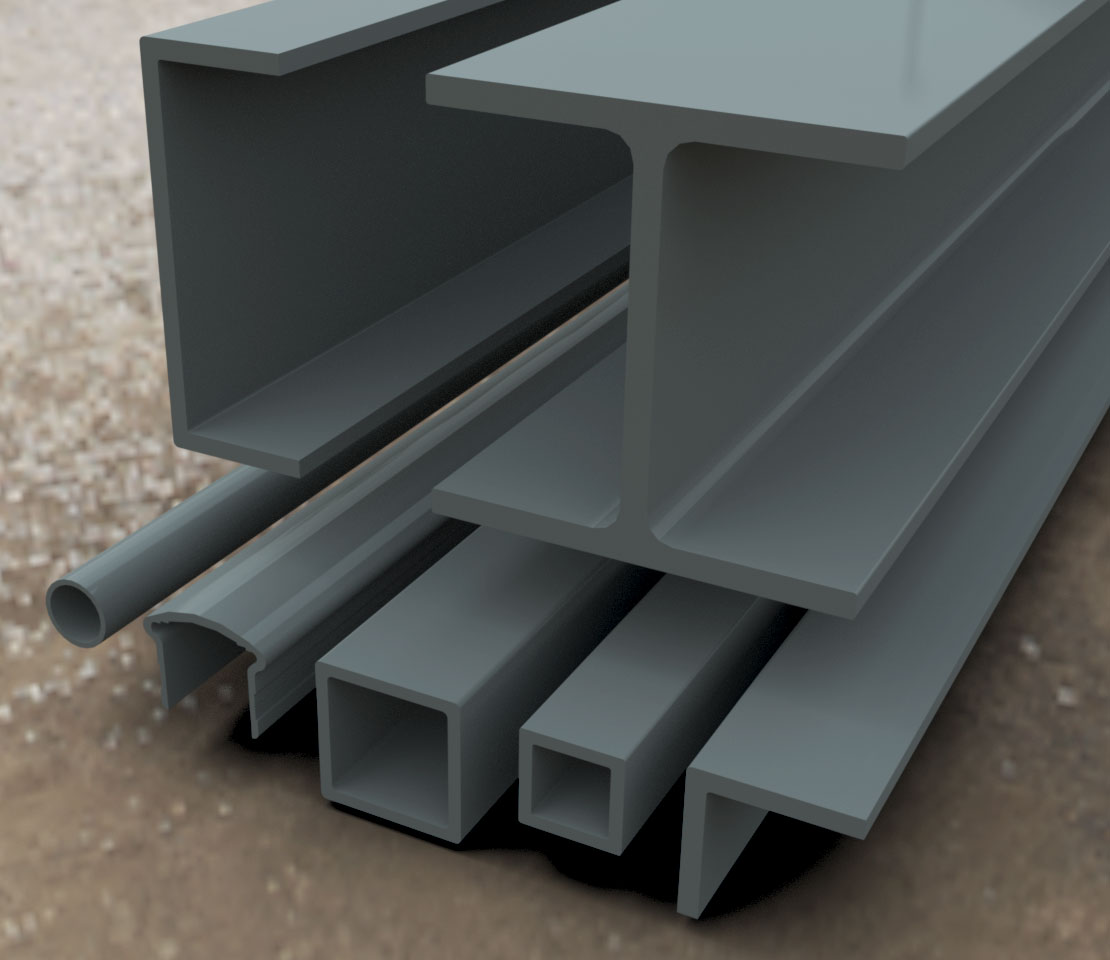

We specialise in both moulded and pultruded GRP gratings, along with a full range of complementary products including handrails, stair treads, and structural support frames. Whether you’re working in marine, industrial, chemical, our GRP products offer durable, corrosion-resistant products that perform. As well as being a low-maintenance alternative to traditional materials.

GRP is a solution, not just a material

Whether you’re focused on safety, durability, or regulatory compliance, our GRP products deliver dependable performance in the toughest conditions. Let us help you find the right solution tailored to your needs.

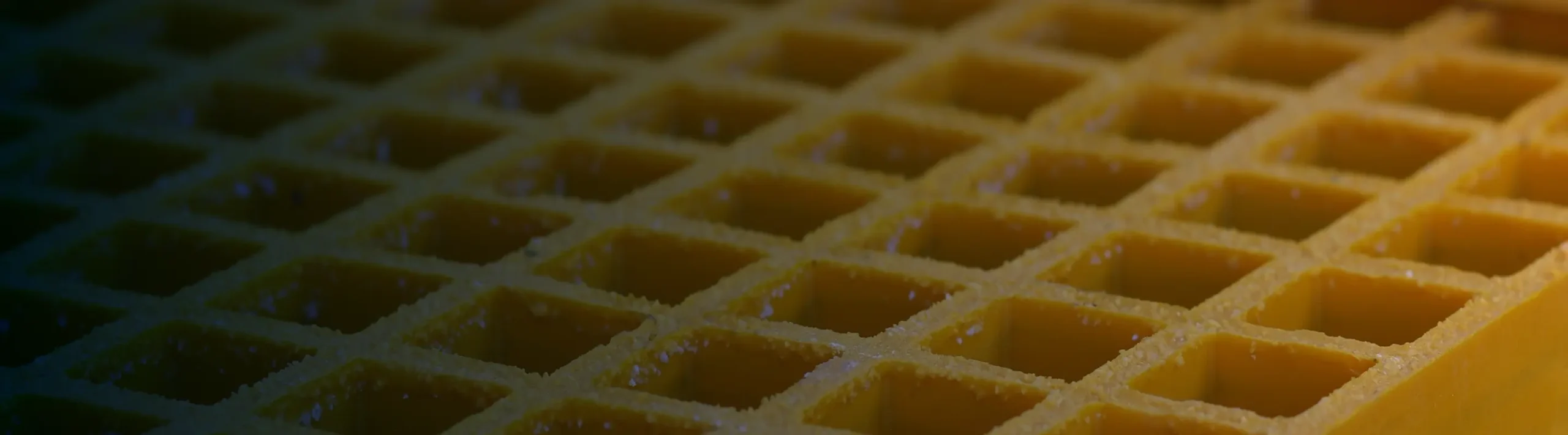

GRP Grating Range

Why Choose GRP?

Glass Reinforced Plastic (GRP) offers a powerful combination of performance, safety, and long-term value making it the smart alternative to conventional materials. Here’s why GRP is the material of choice for forward-thinking industries.

Corrosion Resistant

GRP stands up to the toughest environments including exposure to moisture, salt, chemicals, and corrosive gases without rusting or degrading. It’s the ideal solution for wastewater plants, chemical facilities, marine structures, and other harsh settings where durability is critical.

Non-Conductive

Naturally non-conductive, GRP provides built-in electrical insulation, making it a safer option for electrical substations, utilities, and environments with high-voltage equipment. No additional insulation required, just added peace of mind.

Slip Resistant

With its grit-embedded surface, GRP grating offers outstanding traction, even in wet or oily conditions. This helps prevent slips and falls, improving workplace safety in industrial plants, walkways, and access platforms.

Lightweight

GRP components can weigh up to 75% less than metal, which means easier transport, faster installation, and less need for heavy lifting equipment. That translates into reduced project timelines for you.

Low Maintenance

GRP eliminates the need for additional surface treatments or protective coatings. Its non-porous surface resists grime, chemicals, and UV damage, minimising ongoing maintenance and extending product life.

Durable & Long-Lasting

Engineered for strength and resilience, GRP maintains its structural integrity in extreme temperatures, UV exposure, and corrosive environments. It’s a long-term investment that pays off in reduced replacements and superior performance.

Fire Retardant Options Available

For environments where fire safety is a priority, GRP can be manufactured with fire-retardant resins to meet strict industry standards. Delivering both performance and compliance.

Applications of GRP Products

Glass Reinforced Plastic (GRP) is a high-performance material customised to withstand extreme environments. Lightweight, corrosion-resistant, non-conductive, and highly durable, GRP is trusted across a wide spectrum of industries for both structural and safety-critical applications.

Oil & Gas Applications

GRP is increasingly used in the oil and gas industry, where chemical exposure, explosive environments, and extreme weather are the norm. Its non-conductive and non-sparking properties make it a safer alternative in hazardous locations.

Typical uses include

- Chemical-resistant grating, handrails, and platforms on refineries and rigs.

- Pipe supports and access structures exposed to oil, gas, and chemical vapours.

- Walkways and ladders in onshore and offshore facilities.

These applications help enhance operational safety and reduce maintenance costs in high-risk areas.

Electrical & High-Risk Environments

GRP’s non-conductive nature makes it ideal for electrical installations and environments where arc flash or shock hazards are present.

Applications include

- Cable management systems (trays, ladders).

- Switchgear enclosures and transformer fencing.

When worker safety and regulatory compliance are critical, GRP provides an effective solution without the need for grounding or specialised coatings.

Industrial Applications

In industrial settings such as manufacturing plants, processing facilities, and warehouses, GRP is a reliable alternative to conventional materials.

Key applications include

- Anti-slip gratings and stair treads for the user’s safety.

- Ladders, platforms, and cable trays with non-conductive properties for electrical safety.

- GRP enclosures and protection of high value electrical components.

These features make GRP ideal for industries where worker safety, chemical exposure, and high humidity are ongoing concerns.

Marine & Coastal Applications

The marine sector benefits heavily from GRP due to its exceptional resistance to saltwater, UV radiation, and constant moisture exposure.

Applications include:

- Dock decking, marina walkways, and piers.

- Railing systems and safety ladders for waterfront areas.

- Components for offshore oil platforms and coastal infrastructure.

GRP won’t corrode, swell, or require constant painting, offering lower lifecycle costs and less downtime for maintenance.

Transportation & Infrastructure

With its lightweight and high-strength profile, GRP is a preferred material for modern infrastructure projects where corrosion, fatigue, and load-bearing requirements must be addressed.

Applications include

- Pedestrian bridges, catwalks, and overpasses.

- Highway sound barriers and anti-glare screens

- Public transportation shelters, platforms, and stair structures

GRP structures are quick to install, resistant to environmental damage, and virtually maintenance-free, making them ideal for long-term infrastructure investments.

Technical Capabilities

We understand that every project is unique. Our technical team is equipped to deliver tailored GRP solutions to match your exact specifications.

Our capabilities include:

- Wide range of panel sizes, thicknesses, and mesh patterns.

- Custom cutting and shaping to suit complex customised.

- Pultruded profiles with various wall thicknesses and load ratings.

- Modular systems for quick assembly on-site.

- CAD-supported customised assistance for precision fitting.

- Tolerance matching to industry standards and custom project specs

Whether you need exact dimensions, unusual spans, or specific fire ratings, we can deliver a solution that fits.

Why Choose Us?

At Oasis Metal, we bring together decades of expertise, precision engineering, and a customer-first approach to deliver industry-leading GRP (Glass Reinforced Plastic) solutions. Here’s why clients across multiple industries trust us:

Expertise & Experience

Our team has developed a deep understanding of composite materials and their wide-ranging applications. From standard components to custom-engineered solutions, we combine technical know-how with innovative thinking to meet even the most complex project requirements.

Quality Assurance

Quality is at the core of everything we do. Every product undergoes rigorous inspection and testing to ensure it meets strict industry standards for durability, safety, and performance. We’re committed to delivering solutions you can rely on, every time.

Dedicated Customer Support

From initial consultation to final delivery, our experienced team is here to support you at every stage. We offer expert customised advice, tailored product recommendations, and responsive after-sales service to ensure your project runs smoothly from start to finish.

FAQ’s

What’s the difference between moulded and pultruded GRP gratings?

Moulded gratings offer bi-directional strength and are ideal for corrosive or wet environments, while pultruded gratings provide greater span capability and higher unidirectional strength, ideal for heavy-duty applications.

Can GRP be used outdoors?

Absolutely. Our GRP products are UV resistant and customised to withstand outdoor weather conditions, including marine and coastal exposure.

Are your products compliant with safety standards?

Yes. Our GRP products meet industry standards for fire retardancy, slip resistance, and structural performance.

Do you offer custom fabrication or cutting?

Yes, we offer factory tailored cutting, drilling, and shaping to suit individual project requirements, ensuring a perfect fit.

How long does it take to deliver custom orders?

Lead times vary based on the complexity and volume of the order, but we pride ourselves on working to tight deadlines. Contact us for a tailored lead time estimate.