Our moulded GRP gratings are produced using a high-strength combination of fibreglass roving fibre and thermosetting resin, cured within a precision mould. The result is a durable grating panel with uniform load distribution in both directions.

These gratings are particularly well-suited to corrosive environments, offering high resistance to chemicals, saltwater, and moisture, they also offer excellent anti-slip properties in safety-critical areas.

Our GRP is available in a variety of mesh sizes, and resin types, such as fire-retardant options, and surface finishes to match application needs. Moulded gratings can be easily cut to size on-site without compromising structural integrity.

Key Benefits

Excellent bi-directional strength

Superior corrosion and chemical resistance

Slip-resistant surface, especially with grit finishes

Ideal for wet or hazardous environments

Typical Uses Include

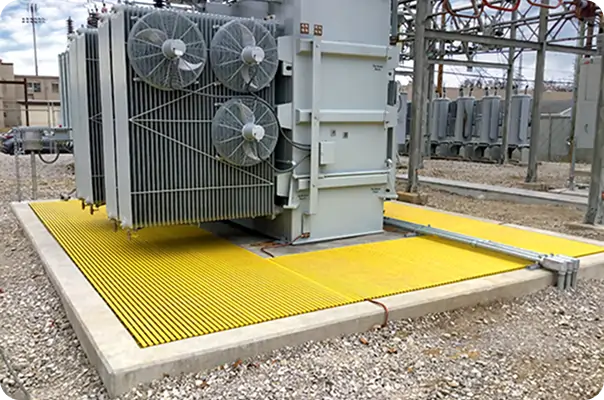

Chemical processing plants, marine docks, water treatment plants, and electrical installations.

Chemical processing plants

Marine docks

water treatment plants

Electrical installations

Common Applications

Walkways, platforms, trench covers, chemical plants, wastewater facilities.

FAQ’s

What’s the difference between moulded and pultruded GRP gratings?

Moulded gratings offer bi-directional strength and are ideal for corrosive or wet environments, while pultruded gratings provide greater span capability and higher unidirectional strength, ideal for heavy-duty applications.

Can GRP be used outdoors?

Absolutely. Our GRP products are UV resistant and designed to withstand outdoor weather conditions, including marine and coastal exposure.

Are your products compliant with safety standards?

Yes. Our GRP products meet industry standards for fire retardancy, slip resistance, and structural performance.

Do you offer custom fabrication or cutting?

Yes, we offer factory tailored cutting, drilling, and shaping to suit individual project requirements, ensuring a perfect fit.

How long does it take to deliver custom orders?

Lead times vary based on the complexity and volume of the order, but we pride ourselves on working to tight deadlines. Contact us for a tailored lead time estimate.