At Oasis Metal Manufacturing, we are dedicated to providing top-quality ladder and scaffolding solutions that cater to a variety of needs. Whether you’re a professional contractor or a DIY enthusiast,…

Read More

Designed for safety and efficiency, our handrails are perfect for both industrial and commercial use. Made from high-quality materials, they offer long-lasting performance and resistance to environmental factors. Elevate your…

Read More

Welcome to Oasis Metal Manufacturing – Your Premier Source for Fiber Reinforced Plastic (FRP) Solutions At Oasis Metal Manufacturing, we specialize in providing top-tier fiber reinforced plastic (FRP) products designed…

Read More

Fixing Clips: Essential for Secure Grating Installation Secure and easy to install, our fixing clips ensure stable and reliable fastening for gratings. Available in both Mild Steel and Stainless Steel,…

Read More

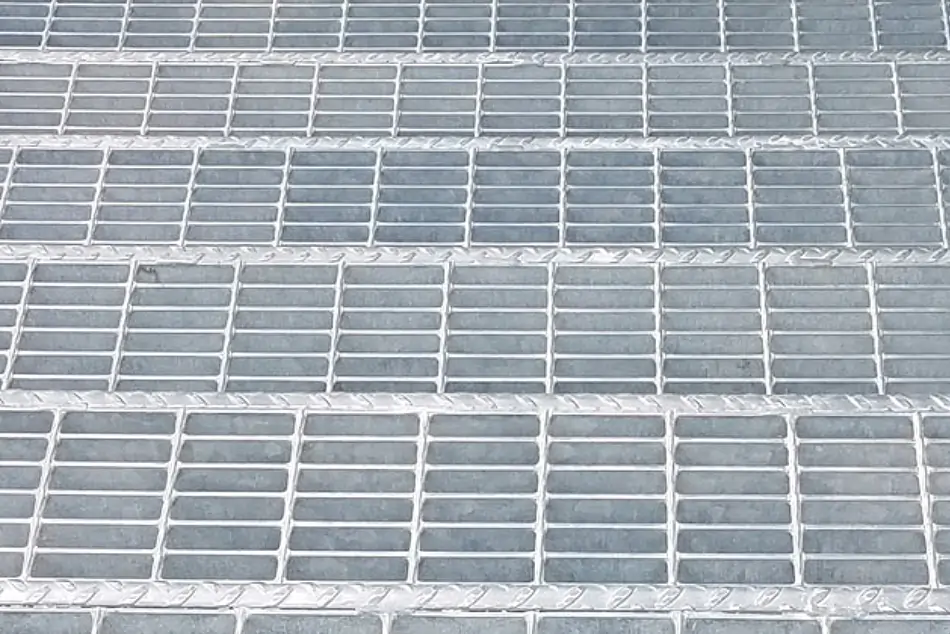

Standard Gratings Adaptable and Strong for All-round Use Our gratings are engineered for a wide range of industrial and architectural applications. Available in various sizes and configurations, including load-bearing bars…

Read More

Durable and Customizable for Safe Access Our Stair Treads offer robust solutions for secure, slip-resistant access in any setting. Available in both Mild Steel and Stainless Steel, these treads are…

Read More

Staircases by Oasis Metal Manufacturing: Safe, Functional, and Aesthetically Pleasing Solutions Staircases are essential elements that connect different levels within a building, providing safe and easy access between floors. At…

Read More

O.Fence is leading manufacturer of welded wire mesh fence products. Providing wide range of perimeter security solution. Whether you’re looking for fencing solutions, shelving systems, or customized mesh designs, O.fence…

Read MoreSteel gratings are commonly used in industrial and commercial applications in the UAE. These include walkways, platforms, stair treads, and drainage systems for factories, power plants, and offshore oil platforms. Steel gratings offer high load-bearing capacity, durability, and resistance to high temperatures, making them ideal for demanding environments.

Steel gratings are designed for strength and versatility, while GI gratings are treated with a zinc coating to prevent corrosion. GI gratings are preferred for outdoor applications or projects where exposure to moisture is a concern, such as drainage systems and outdoor platforms, due to their resistance to rust.

Yes, we offer customizations for all our grating products. Oasis Metal Manufacturing can provide tailored solutions, including specific sizes, shapes, load capacities, and surface finishes to match the exact needs of your project. Our team works closely with clients to ensure their gratings meet both functional and aesthetic requirements.

At Oasis Metal Manufacturing, our grating clamps are made from durable, corrosion-resistant materials to ensure long-lasting performance. They are easy to install and designed to accommodate a variety of grating sizes and configurations. Whether you are installing steel gratings, our clamps provide the reliability and security needed for any application.

Yes, We offer after-sales services, including maintenance and repair, to ensure that your gratings continue to perform optimally for years to come. Whether you need technical assistance or regular maintenance, Oasis Metal Manufacturing is here to help.