At the core of our promise to deliver not just products, but solutions, stands our Engineering Department. Staffed by a team of highly qualified engineers, we are equipped to offer unparalleled technical advice and support, ensuring that your project’s specifications are not just met, but exceeded with precision and foresight.

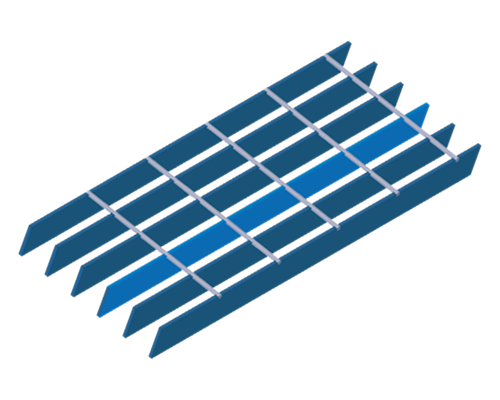

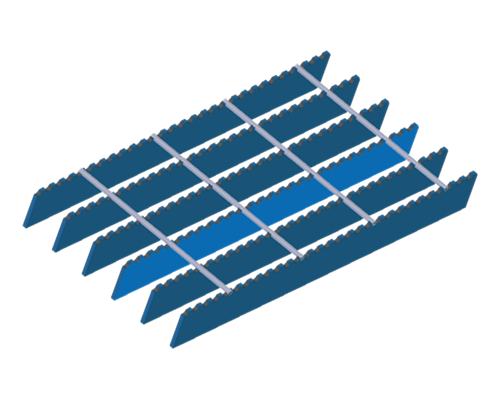

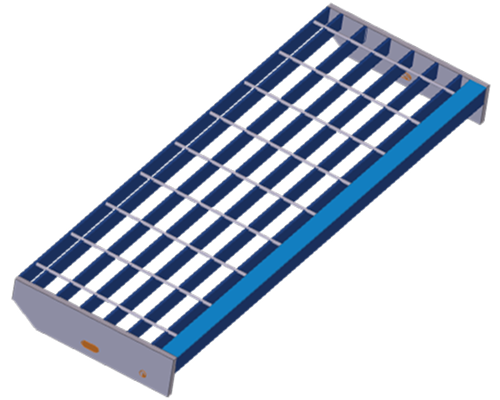

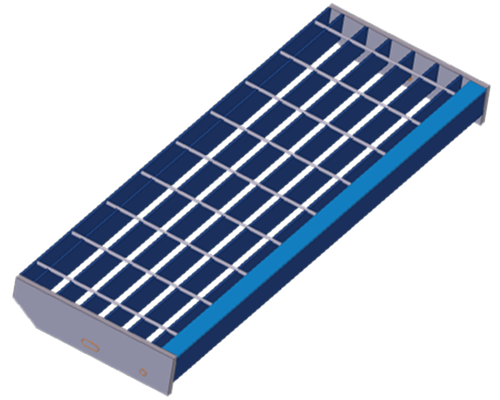

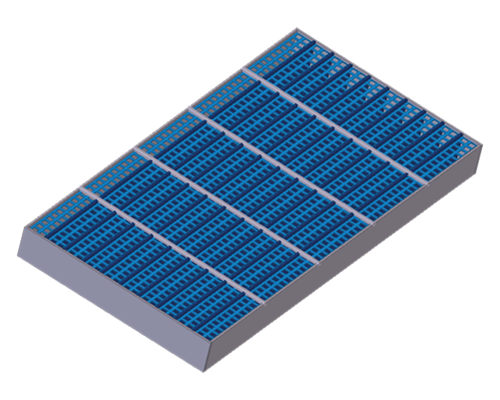

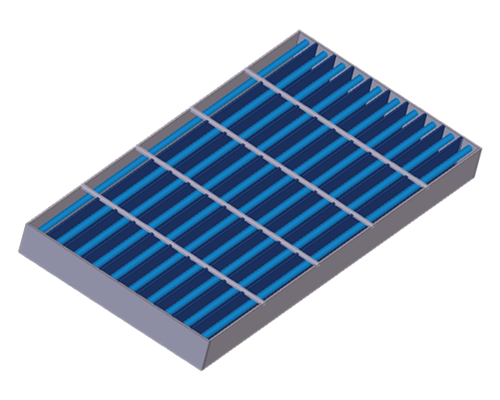

A steel grid formed from load bearing bars and cross bars through resistance welding.

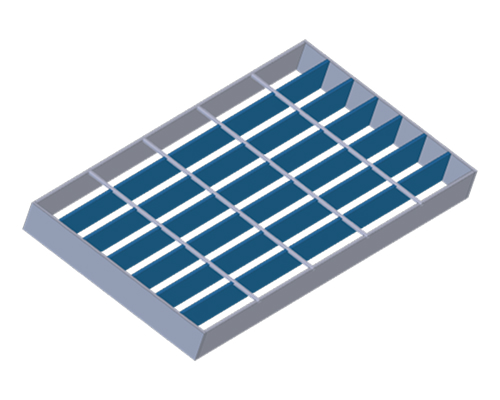

Direction of the load bearing bars.

Direction of the cross bars.

Load bearing bar with plain top surface.

Load bearing bar with serrated top surface.

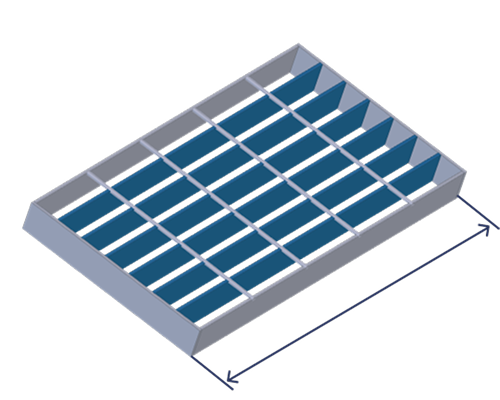

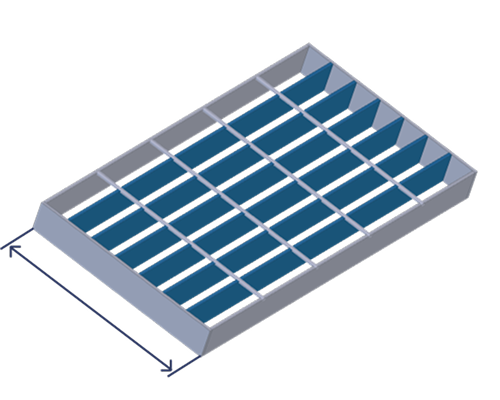

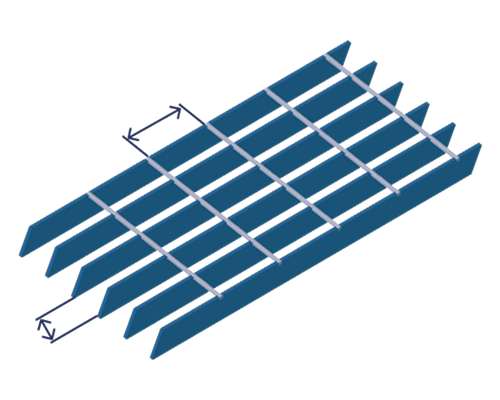

The centre-to-centre distance between load bearing bars or cross bars.

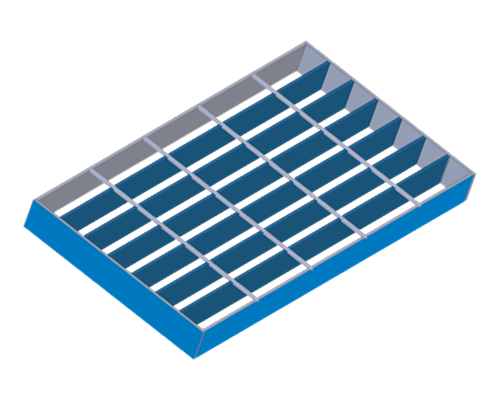

Flat bar welded to close fabricated panels at each end and or around cut outs.

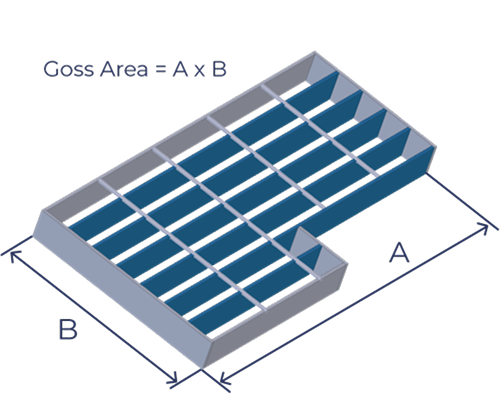

Total area of gratings including cut-out areas.

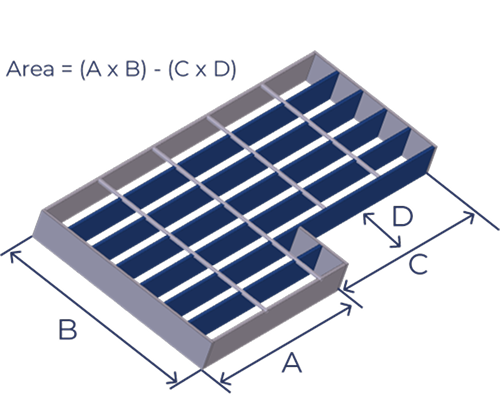

Total area of gratings excluding cut-out areas.

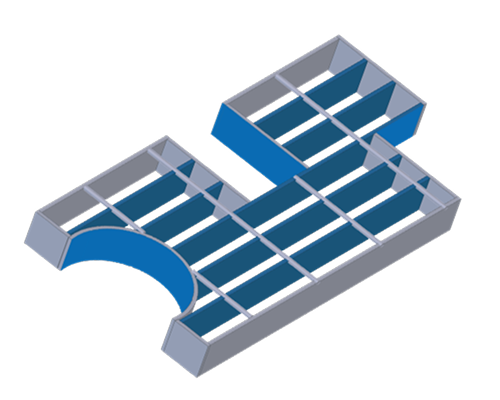

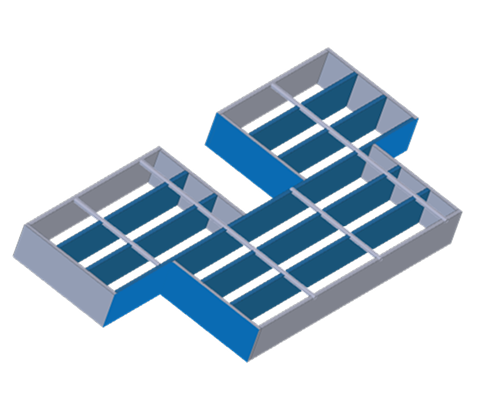

Area of grating cut out for pipes and columns to pass through.

Cut-out with straight edges.

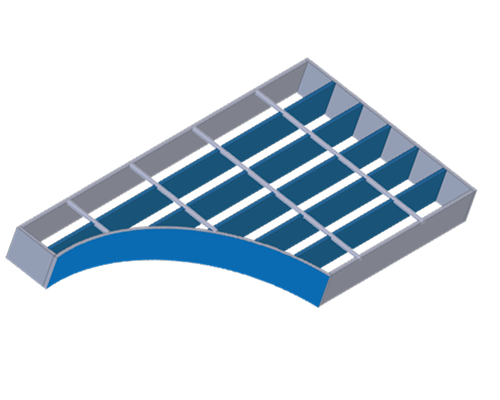

Cut-out with curved edges.

Larger size flat bar welded to the edge of grating panels for safety purposes.

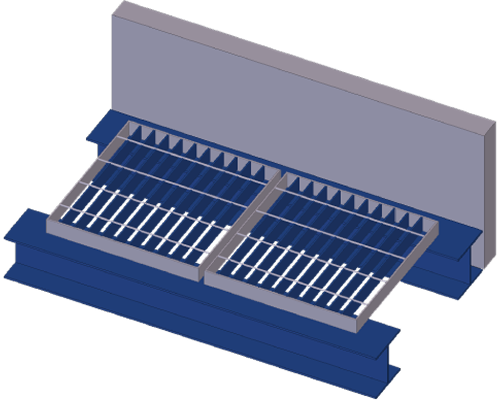

An angle fixed to concrete or steelwork to support gratings.

The distance from grating edge to an adjacent panel or structure.

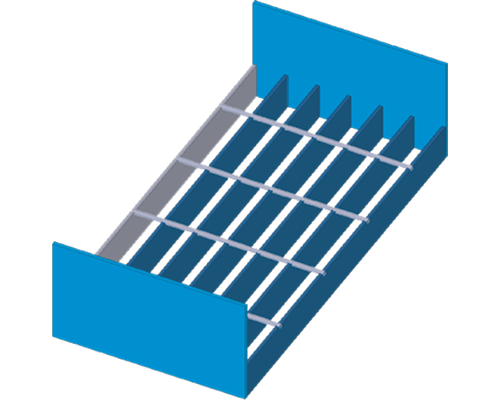

End plates welded Stair Treads to permit fixing to steelwork.

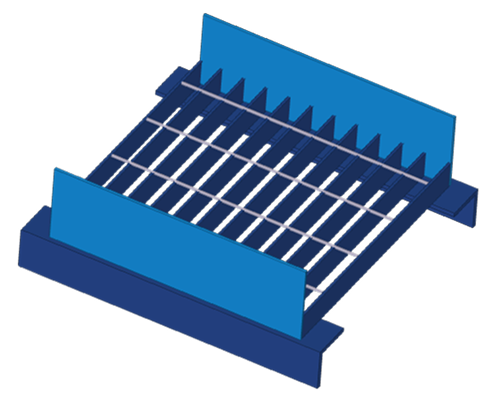

Nosing bar welded stair treads or gratings to provide additional slip resistance.

This is used to prevent a 15mm or 20mm ball passing through the grating. The gratings have an additional round bar welded to underside of cross-rods.

Infill strip is welded between load bars, to prevent small objects passing through the gratings.

Still unclear on any aspects of the terminology. We’re happy to clarify and help you choose the exact product for your project.

Contact for Expert Advice